Capabilities and Capacities in Precision CNC Machining

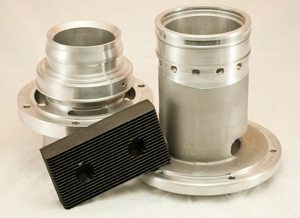

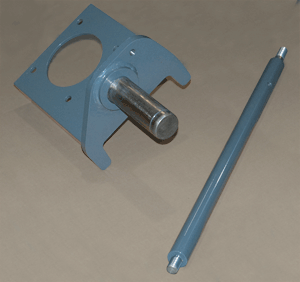

Customers seek out Versatech for our ability to meet the most stringent specifications. Our core competency is precision parts production, and advanced CNC machining and turning centers enable us to produce the most difficult components.

Contact Versatech today for the peace of mind that your order will be delivered “in tolerance, on time.”

Our horizontal, vertical, and lathe CNC centers feature:

- Multi-part fixturing

- Pallet-shuttle loading

- Synchronous Tapping

- Helical interpolation

- Tool management

- Parts probing

- CNC lathes with milling/drilling, and 4th axis capabilities

- CNC manufacturing cells

What Separates Versatech from the Competition?

Capabilities in Large Part Manufacture

Large and difficult parts are a Versatech specialty. We deliver welded component assemblies up to 2100 millimeters (nearly 7 feet) in length for the electrical industry, and machining single parts up to 48” X 72” is no stretch of our capabilities. Want to know more, contact us today.

Welding and Finishing Services

Versatech handles complex weldments and component assembly quickly, relying on our Motoman multi-axis welding robots. Learn more on our Equipment page.

Parts and component assemblies are deburred, polished, and packaged as needed, including wrapping in air-tight and moisture proof paper.

Lean Manufacturing and ISO Certification

Versatech is ISO 9000-2001 and ISO 14000 compliant. We are constantly pushing the envelope for efficient, high-quality production. We utilize Lean Manufacturing methods including poke yoke (mistake proofing), SMED (Single-Minute Exchange of Die), 5S (five disciplines for maintaining an effective workplace), cell manufacturing, and more.

Visit our Manufacturing Methods page for more information.