Manufacturing Methods

Quality Assurance

Meeting the most stringent specifications is at the heart of everything we do. That makes quality assurance a critical operation at Versatech.

Our employee commitment to ISO 9000-2001 and ISO 14000 standards means defect free deliveries, with a Total Quality System that keeps it that way.

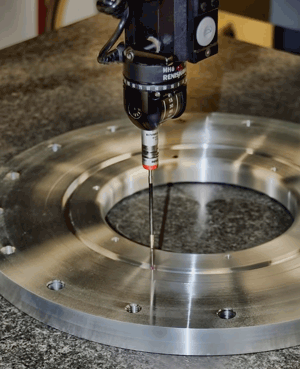

CMM Monitoring

Versatech’s Quality Assurance Department makes use of CMM (coordinate measuring machines) to determine part compliance. Each CMM station uses a touch probe to determine size and position across X, Y, and Z axes with micrometer precision.

Programmed to repeatedly measure identical parts, our CMM stations help us meet our customers’ tolerance requirements cost-effectively.

Lean Manufacturing

At Versatech, our manufacturing cells are strategically positioned to make each operation as efficient as possible. As a company, we are committed to lean manufacturing, not only because it makes us more competitive, but because it enables us to deliver quality machined parts today and the confidence to deliver even higher quality tomorrow.

- Poke Yoke (an error avoidance system for fool proofing operations)

- SMED (rapid change over from producing one part to the next)

- 5S (Sort, Set In Order, Shine, Standardize, and Sustain – a system of continual improvement)

- 6 Sigma Black Belts on staff (strengthening a culture of lean manufacturing through team leadership)

- Kaizen Blitzes (a focused, short term project to improve a process)

- Try-Storming (a kind of action oriented “brainstorming” where practical solutions are put to use)

- 20 Keys (benchmarking and diagnostic methodologies for maintaining lean production)

- Cellular Manufacturing Techniques (combining CNC lathes with CNC mills)

Machine Maintenance

The traditional plague of machine shops, the breakdown, is continually minimized at Versatech.

As part of our Total Productive Maintenance philosophy, Versatech machinists are trained in and aware of the ongoing maintenance issues of each machine. That means problems are caught early or avoided entirely. Our maintenance training and in-house capabilities allow us to repair machines on-site, quickly, and with little downtime.

One Touch Management

Floor supervisors visit each manufacturing cell 3 times daily, meeting with the operators at specified times to go over a list of queries related to the production run.

The goal of this “one touch” approach is simple: to catch problems and potential problems early, when they can be addressed effectively and without undo cost or wasted time,

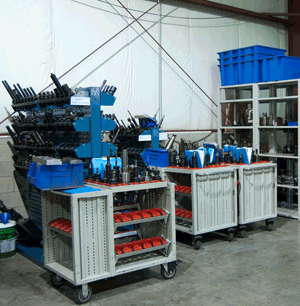

Tool Management

Exceptional tool management is an important asset at Versatech. No time is lost looking for a needed tool or dealing with a broken tool.

Our Tool Management department makes sure that each station has on-hand the quality tools they need to complete each of their tasks without having to leave a production cell to find something. Tool Management also tracks tool wear and tear, making sure no time is lost by the untimely failure of a worn tool.